Application example 1

|

|

|

Application example 2

|

|

Application example 3

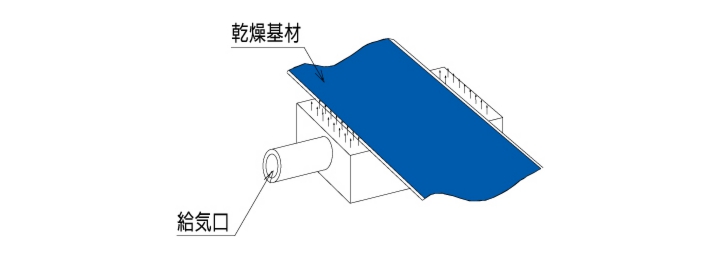

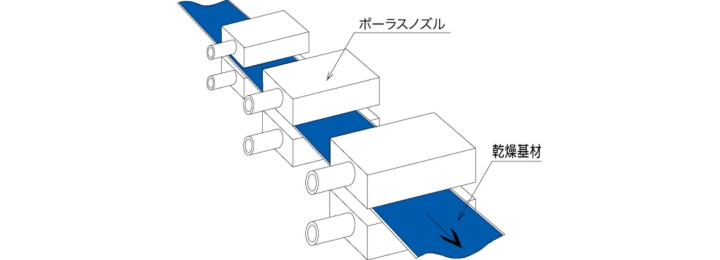

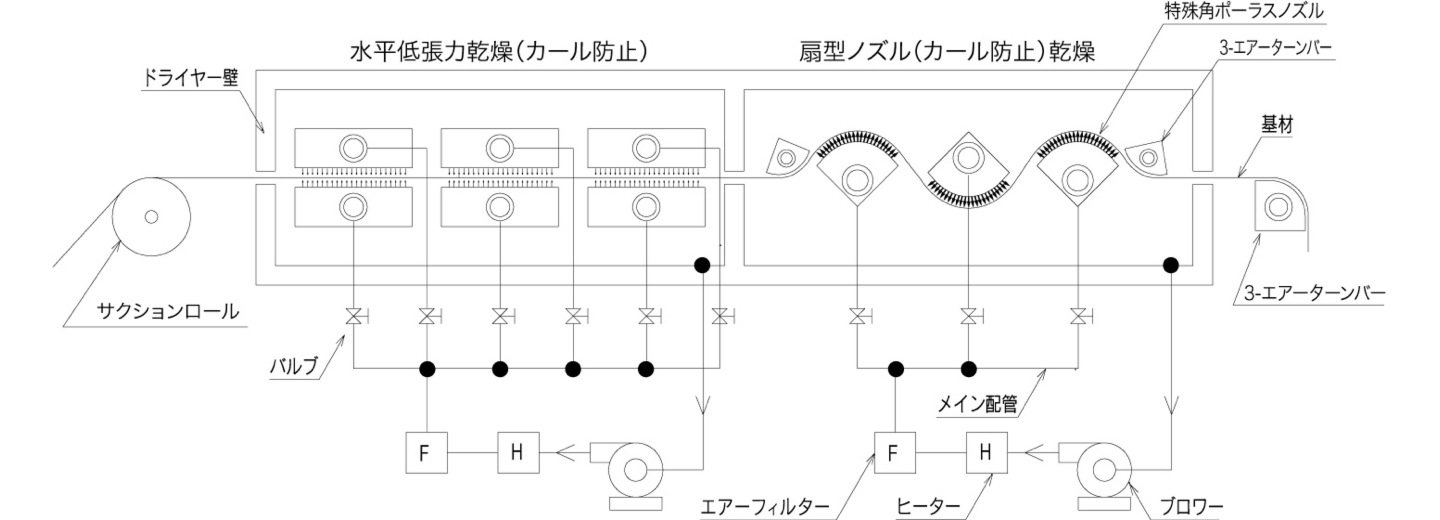

Floating Dryer

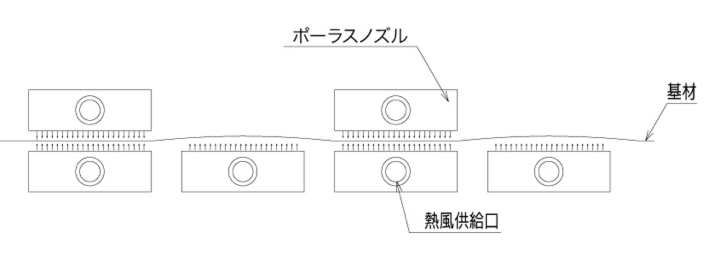

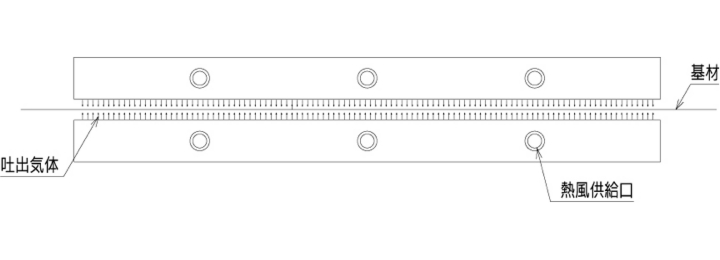

The image below shows a floating dryer using a perforated nozzle with a porous plane surface which placed either on one or both sides of the material can achieve one tenth of air speed (1m / sec) of the conventional porous board, floating and drying products on a stream of hot air.

- Special features

- ①Enables ultra-low tension transport.

- ②Low tension transport prevents creasing of the product.

- ③The area of porous nozzle is wide, uniform and delivers low air speed, preventing drift.

- ④Floating on lower wind speed protects the coated surface from damage and skinning.

- ⑤Expelling hot air from the porous nozzle prevents from unbalancing due to thermal deformation of slit gaps of the conventional floating slit nozzles.

- ⑥Enables use of non-contact CPC (centering).

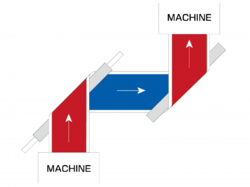

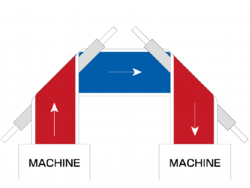

Application example 5In-plane crank turn

|

|

|

管理者の許諾を得ずに、当サイト内のあらゆる画像や文章をなどの情報を無断転載することは、著作権侵害にあたる行為のため禁止します